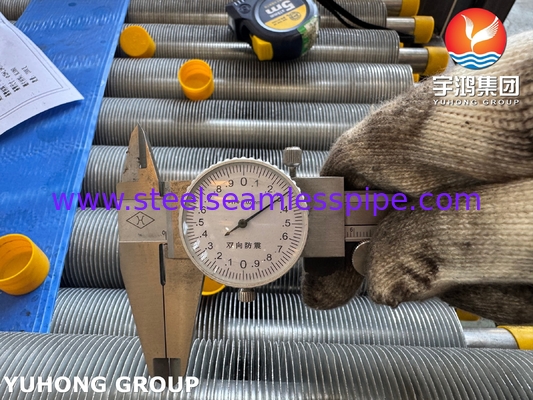

EN 10217-7 1.4301 Extruded Fin Tube With Aluminum 1060 Fin For Air Heaters

This high-efficiency bimetallic finned tube is primarily used in heat exchangers. The core tube is made of stainless steel, and the fins are made of aluminum. An aluminum sleeve (future fin) is pulled over the stainless steel core tube. The assembly is pulled through a machine with a set of rotating disks or rollers. These tools squeeze (press and form) the aluminum outward from the tube, forming the fins, while simultaneously deforming the aluminum inward under high pressure, forming a metallurgical bond with the outer wall of the steel tube.

European standard EN 10217-7 specifies the technical delivery conditions for welded steel tubes for pressure purposes.

1.4301 stainless steel is equivalent to AISI 304 or UNS S30400 in the US system. It offers excellent corrosion resistance in a wide range of environments and good mechanical properties over a wide temperature range.

It provides a strong, corrosion-resistant base for heat exchanger tubes and is suitable for use with a variety of industrial fluids (water, steam, certain chemicals, and oils).

1060 aluminum fins have a thermal conductivity of ~235 W/m·K, significantly higher than steel (stainless steel is approximately 16 W/m·K). This is the primary reason for using aluminum – it efficiently absorbs heat from the tube and dissipates it to the air or other gas. It is highly machinable and ductile.

EN 10217-7 1.4404 Chemical Composition Tables

| Designation | Chemical composition (% by mass – max unless stated) |

| Steel name | Steel No. | C | Si | Mn | P | S | Cr | Mo | Ni | Cu | N | Other | |

| Austenitic steel | |

| X2CrNi18-9 | 1.4307 | 0.03 | 1.00 | 2.0 | 0.045 | 0.015 | 17.50

/19.5 | – | 8.0

/10.0 | – | 0.11 | – | |

| X2CrNi19-11 | 1.4306 | 0.03 | 1.00 | 2.0 | 0.045 | 0.015 | 18.00

/20.0 | – | 10.0

/12.0 | – | 0.11 | – | |

| X2CrNiN18-10 | 1.4311 | 0.03 | 1.00 | 2.0 | 0.045 | 0.015 | 17.00

/19.5 | – | 8.50

/11.5 | – | 0.12

/0.22 | – | |

| X5CrNi18-10 | 1.4301 | 0.07 | 1.00 | 2.0 | 0.045 | 0.015 | 17.00

/19.5 | – | 8.00

/10.5 | – | 0.11 | – | |

| X6CrNiTi18-10 | 1.4541 | 0.08 | 1.00 | 2.0 | 0.045 | 0.015 | 17.00

/19.0 | – | 9.00

/12.0 | – | – | Ti

5xC

/0.70 | |

| X6CrNiNb18-10 | 1.4550 | 0.08 | 1.00 | 2.0 | 0.045 | 0.015 | 17.00

/19.0 | – | 9.00

/12.0 | – | – | Nb

10xC

/1.00 | |

| X2CrNiMo17-12-2 | 1.4404 | 0.03 | 1.00 | 2.0 | 0.045 | 0.015 | 16.50

/18.5 | 2.0

/2.5 | 10.00

/13.0 | – | 0.11 | – | |

| X5CrNiMo17-12-2 | 1.4401 | 0.07 | 1.00 | 2.0 | 0.045 | 0.015 | 16.50

/18.5 | 2.0

/2.5 | 10.00

/13.0 | – | 0.11 | – | |

| XCrNiMoTi17-12-2 | 1.4571 | 0.08 | 1.00 | 2.0 | 0.045 | 0.015 | 16.50

/18.5 | 2.0

/2.5 | 10.50

/13.5 | – | – | Ti

5xC

/0.70 | |

The advantages of Extruded Fin Tube

The primary advantage of extruded finned tubes lies in their unparalleled heat transfer efficiency, achieved through a seamless bond and superior mechanical strength. While their initial cost is higher than simple finned tubes, they offer

higher thermal performance, enabling smaller and more compact heat exchangers for the same load.

Higher reliability and a longer service life reduce downtime and maintenance costs.

They are durable in demanding applications.

This makes them a top choice for critical applications such as power plants, refineries, HVAC systems, and industrial process cooling, where performance, reliability, and service life are paramount.

Applications

Air-cooled steam condenser (ACSC)

Generator hydrogen cooler

Radiant cooler

HVAC&R

Heating coils

Cooling/evaporator coils

Condenser coils

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!