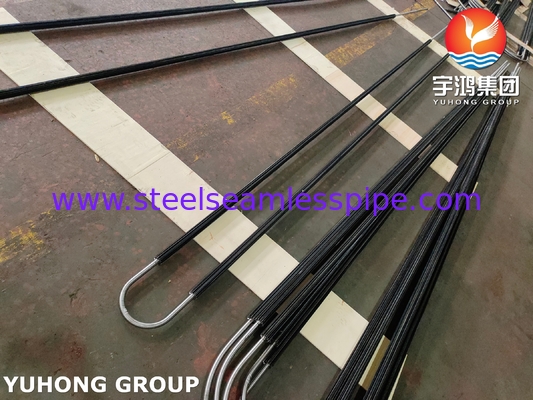

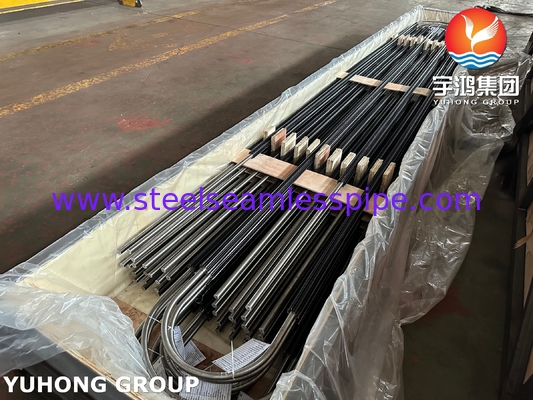

ASTM A179 Σωλήνες με εγκάρσια πτερύγια από ανθρακούχο χάλυβα U Bend Συγκολλημένοι κατά μήκος για έργα διύλισης πετρελαίου

Οι σωλήνες με εγκάρσια πτερύγια κατά μήκος είναι παρόμοιοι με τους συγκολλημένους σωλήνες με σπειροειδή πτερύγια. Αυτή η δομή συγκόλλησης μπορεί να χρησιμοποιηθεί σε οποιαδήποτε πραγματική εφαρμογή μεταφοράς θερμότητας. Η δομή με εγκάρσια πτερύγια χρησιμοποιείται συνήθως σε εφαρμογές κελύφους και σωλήνων, με τη θερμότητα να μεταφέρεται μεταξύ του ρευστού που ρέει μέσα από τις οπές των σωλήνων με πτερύγια και του ρευστού που ρέει μέσα από τις οπές του κελύφους.

Διαδικασία κατασκευής: Οι σωλήνες με εγκάρσια πτερύγια κατά μήκος παράγονται με συγκόλληση με αντίσταση πτερυγίων κατά μήκος του σωλήνα. Τα πτερύγια έχουν σχήμα U. Ο βασικός σωλήνας κόβεται στο κατάλληλο μήκος και στη συνέχεια τα πτερύγια προσανατολίζονται και συγκολλώνται με αντίσταση κατά μήκος του σωλήνα.

Κοινό υλικό βασικού σωλήνα/σωλήνα: ανθρακούχο / κράμα χάλυβα (A106, A179, A335 P5, P22, P9, κ.λπ.) ανοξείδωτο χάλυβα TP304, TP316L, TP321, κ.λπ. κράμα χαλκού CuNi 70/30, CuNi 90/10, κ.λπ. και άλλο υλικό. Γενικά, το υλικό των πτερυγίων είναι το ίδιο με το υλικό των βασικών σωλήνων.

Πλεονεκτήματα

1. Ενίσχυση της απόδοσης μεταφοράς θερμότητας εντός του αποτελεσματικού χώρου.

2. Μείωση του χώρου εγκατάστασης που απαιτείται για τις επιφάνειες μεταφοράς θερμότητας.

3. Μείωση του κόστους του εξοπλισμού διατηρώντας παράλληλα υψηλή λειτουργική αξιοπιστία.

4. Μείωση της πτώσης πίεσης στην πλευρά του σωλήνα, μειώνοντας έτσι το λειτουργικό κόστος.

5. Αύξηση της ακαμψίας του χαλύβδινου σωλήνα και ενίσχυση της σεισμικής του αντοχής.

6. Ενίσχυση της μεταφοράς θερμότητας, μείωση της αντίστασης ροής και της κατανάλωσης μετάλλου.

| Χημική Σύνθεση |

C |

Mn |

P≤ |

S≤ |

Si≤ |

| 0.06-0.18 |

0.27-0.63 |

0.035 |

0.035 |

0.25 |

| Μηχανική Ιδιότητα |

Ελάχιστη αντοχή σε εφελκυσμό |

Ελάχιστη αντοχή διαρροής |

Επιμήκυνση (%) |

| 47ksi, 325MPa |

26ksi, 180MPa |

≥35 |

|

* Η χαμηλή περιεκτικότητα σε άνθρακα παρέχει εξαιρετική συγκολλησιμότητα και μορφοποίηση, αλλά περιορίζει τη σκληρότητα και την αντοχή στη διάβρωση.

* Ο συνδυασμός επαρκούς αντοχής και υψηλής επιμήκυνσης (ελαστικότητα) το καθιστά ανθεκτικό σε μηχανικούς κραδασμούς και επιτρέπει την κάμψη και τη διαμόρφωση.

|

Δοκιμές: Δοκιμή εφελκυσμού εγκάρσια ή κατά μήκος, Δοκιμή ισοπέδωσης, Μέγεθος κόκκων, Δοκιμή διαστολής, Δοκιμή φλάντζας, Δοκιμή σκληρότητας, Υδροστατική δοκιμή ή Μη καταστροφική ηλεκτρική δοκιμή.

Τυπικά σενάρια εφαρμογής σε Oil Refinery

1. Προθερμαντήρας αέρα του κλιβάνου θέρμανσης (Airlpreheater): Ανακτά τη υπολειπόμενη θερμότητα από τα καυσαέρια υψηλής θερμοκρασίας χρησιμοποιώντας τον αέρα καύσης χαμηλής θερμοκρασίας. Αυτή είναι μια κλασική εφαρμογή των σωλήνων με εγκάρσια πτερύγια. Τα καυσαέρια ρέουν από την πλευρά του κελύφους (πλευρά με πτερύγια) και ο αέρας ρέει από την πλευρά του σωλήνα.

2. Αντιδραστήρας και εναλλάκτης θερμότητας προϊόντων/τροφοδοσίας μονάδας υδρογόνωσης: Χρησιμοποιήστε τα θερμά προϊόντα αντίδρασης για να προθερμάνετε τις κρύες πρώτες ύλες. Το αέριο διεργασίας ρέει από την πλευρά του κελύφους (πλευρά πτερυγίων).

3. Ψύκτες για φυσικό αέριο και αέριο διυλιστηρίου: Ψύξτε διάφορα ρεύματα αερίου διεργασίας.

4. Ψύκτες αέρα: Αν και οι ψύκτες αέρα χρησιμοποιούν συνήθως οριζόντιους σωλήνες με πτερύγια, σε ορισμένες συγκεκριμένες περιπτώσεις, χρησιμοποιούνται επίσης κάθετοι σωλήνες με πτερύγια. Οι ανεμιστήρες αέρα αναγκάζουν τον αέρα να φυσά πάνω από τις δέσμες σωλήνων με πτερύγια, ψύχοντας το ρευστό διεργασίας μέσα στους σωλήνες.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!